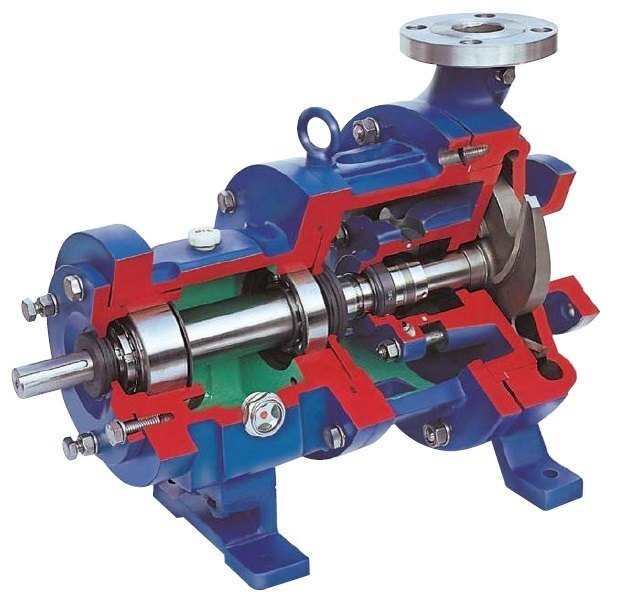

ANSI Series Centrifugal Pump

ANSI Series Centrifugal Pump Specification

- Flow Rate

- Up to 2000 m/hr

- Theory

- Centrifugal

- Material

- Cast Iron, Stainless Steel, Alloy Steel, Duplex Steel

- Structure

- Back Pull Out Design

- Suction Type

- End Suction

- Volute Type

- Single Volute

- Nozzle Location

- Top Centreline Discharge

- Shaft Orientation

- Horizontal

- Power Source

- Electric Motor Driven

- Pressure

- Up to 16 bar

- Temperature

- -40C to 150C

- Inlet, Outlet Diameter

- Inlet: 50 mm to 300 mm, Outlet: 32 mm to 250 mm

- Speed

- Up to 3600 rpm

- Service

- Continuous Duty

- Impeller Type

- Closed

- Casing Pressure Rating

- 150 psi

- Liquid Handling Capacity

- Clear and Slightly Turbid Liquids

- Direction of Rotation

- Clockwise (from drive end)

- Seal Type

- Mechanical Seal / Gland Packing

- Coupling Type

- Flexible Coupling

- Painting

- Anticorrosive Epoxy

- Design Standard

- ANSI B73.1

- Maximum Viscosity

- Up to 200 cP

- Bearing Type

- Heavy Duty Ball Bearing

- Pump Efficiency

- Up to 85%

- Mounting Type

- Foot Mounted

- Total Head Range

- Up to 100 m

About ANSI Series Centrifugal Pump

Chemical, Petrochemical, Oil & Gas, Water Treatment, Pulp & Paper, Food Processing, Poultry Processing, Automotive, Pharmaceutical, Steel, Power Generation, Textile, Slurry, Acid Transfer, Beverage ProcessingEngineered to ANSI B73.1 Standards

This centrifugal pump series strictly adheres to ANSI B73.1 design, ensuring interchangeability, reliability, and supreme safety for industrial applications. Its robust structure and heavy-duty ball bearings promote consistent performance even in continuous duty cycles under harsh operating conditions.

Versatile Industrial Applications

Ideally suited for chemical processing, petrochemical industries, water treatment, and general industrial services, this pump manages a diverse range of fluids, including clear and slightly turbid liquids, with viscosities up to 200 cP. Its power-driven, flexible-coupling design ensures smooth operation and broad compatibility with modern systems.

FAQs of ANSI Series Centrifugal Pump:

Q: How does the mechanical seal or gland packing benefit pump operation in demanding industries?

A: The mechanical seal and gland packing options minimize leakage and reduce maintenance needs, making the pump ideal for industries like chemical processing and water treatment where reliability and containment are crucial.Q: What is the process for installing and maintaining the foot-mounted ANSI Series Centrifugal Pump?

A: Installation involves securing the foot-mounted base, aligning the flexible coupling, and connecting the electric motor drive. The back pull-out design enables easy maintenance by allowing access to the rotating assembly without disturbing pipework.Q: When should a user opt for the closed impeller design featured in this pump?

A: A closed impeller provides enhanced efficiency and is best chosen for handling clear or slightly turbid liquids, as it minimizes energy loss and delivers superior pumping performance at high speeds and pressures.Q: Where can this centrifugal pump be effectively utilized?

A: It is effectively utilized in chemical, petrochemical, water treatment, and various general industrial settings due to its capability to handle a range of liquids at high efficiencies and withstand extreme operating temperatures and pressures.Q: What are the benefits of the anticorrosive epoxy painting on the pump casing?

A: The anticorrosive epoxy coating offers extended service life by protecting the pump casing from chemical attack, rust, and abrasion, making the pump suitable for aggressive and corrosive environments.Q: How does the heavy-duty ball bearing design enhance continuous duty service?

A: Heavy-duty ball bearings reduce friction, manage high radial and axial loads, and ensure smooth, reliable operation, significantly extending the pumps lifespan in continuous, intensive operation environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Pump Category

Horizontal Side Suction Pumps

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron/Stainless Steel

Shaft Orientation : Horizontal

Power Source : Electric

Suction Type : Other, Side Suction

Ansi-Centrifugal Process Pump

Material : Cast iron stainless steel

Shaft Orientation : Horizontal

Power Source : Other, Electric motor

Suction Type : Other, Singlestage end suction

Sulphuric Acid Transfer Pump

Price 10000.0 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild Steel

Shaft Orientation : Horizontal

Power Source : Electric

Suction Type : Single

Centrifugal Hot Oil Thermic Fluid Pump

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Shaft Orientation : Vertical

Power Source : Electric

Suction Type : Double

|

Denwell Fluid Controls

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |