Most Popular Products

Non Clog Pump

Non Clog Pump Specification

- Flow Rate

- Upto 1500 m/hr

- Theory

- Centrifugal Pump

- Material

- Cast Iron/SS304/SS316

- Structure

- Back Pull-Out Design

- Suction Type

- Flanged Suction

- Volute Type

- Single Volute

- Nozzle Location

- End Suction, Top Discharge

- Shaft Orientation

- Horizontal

- Power Source

- Electric Motor Driven

- Pressure

- Upto 8 kg/cm

- Temperature

- Ambient to 120C

- Inlet, Outlet Diameter

- Inlet: 50-300 mm, Outlet: 40-250 mm

- Speed

- 1440/2900 RPM

- Application

- Effluent, Sewage, Industrial Waste Water, Storm Water

- Insulation Class

- F/H

- Pump Casing

- Robust Cast Iron

- Mounting

- Foot Mounted

- Sealing Arrangement

- Mechanical Seal or Gland Packing

- Maximum Solid Handling

- Upto 100 mm

- Direction of Rotation

- Clockwise (viewed from drive end)

- Impeller Type

- Non-clog, Open/Semi Open

- Noise Level

- Low (as per IS standards)

- Installation Type

- Horizontal Base Mounted

- Shaft Material

- High Tensile Steel / Stainless Steel

- Color

- Blue / Customized

- Protection

- IP 55/ IP 65

- Drive Type

- Direct Coupled

- Bearing Type

- Heavy Duty Ball Bearings

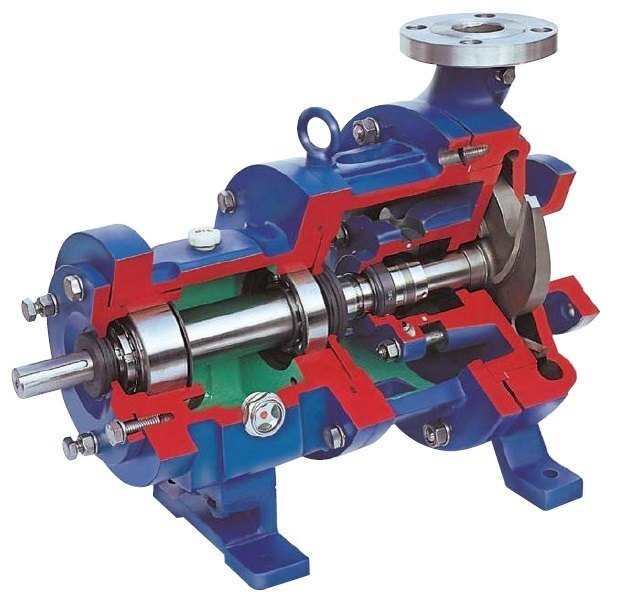

About Non Clog Pump

A non-clog pump generally refers to pumps with a 100% recessed impeller or specially designed open rotor. This design allows the passing of solid objects equal to the width of the discharge of the pump.02-May-2023Efficient Solid Handling

This non-clog pump boasts an impressive ability to handle solids up to 100 mm, making it ideal for applications involving sewage, effluents, and industrial wastewater. Its open or semi-open impeller design ensures reliable operation while minimizing the risk of clogging. The robust cast iron construction withstands abrasive materials for consistent, long-term performance.

Designed for Durability and Safety

Engineered with heavy-duty ball bearings, mechanical seals or gland packing, and insulation class F/H, this pump delivers robust performance under demanding conditions. IP55/IP65 protection prevents ingress of dust and water, while noise levels remain low in accordance with IS standards. The single volute, end-suction, top-discharge configuration optimizes efficiency and safety.

Adaptable Across Industries

Suitable for a wide range of industrial, municipal, and commercial use cases, the pump accommodates flow rates up to 1500 m3/hr, with operating temperatures from ambient up to 120C. Available in various inlet and outlet diameters, with material options such as cast iron, SS304, or SS316, it's a versatile solution for dealers, distributors, exporters, and end users across India.

FAQ's of Non Clog Pump:

Q: How does the non-clog impeller assist in handling challenging fluids?

A: The non-clog impeller, available in open or semi-open configurations, allows the pump to efficiently handle solids up to 100 mm in size. This design helps prevent blockages, making it ideal for sewage, effluent, and industrial wastewater applications.Q: What is the recommended installation process for this pump model?

A: The pump is designed for horizontal, base-mounted installation with foot-mounting. Ensure the pump is securely anchored on a flat surface, aligned for direct coupling with the electric motor, and all flanged connections are sealed properly to avoid leaks.Q: When should I choose a mechanical seal over gland packing for sealing arrangement?

A: Mechanical seals are recommended for applications requiring minimal leakage and lower maintenance, especially with corrosive or hazardous fluids. Gland packing, however, may be preferred for less aggressive applications and where maintenance accessibility is convenient.Q: Where can these pumps be effectively utilized?

A: These non-clog pumps are suitable for sewage treatment plants, municipal wastewater transfer, industrial effluent handling, stormwater management, and other applications involving fluids containing solids. They are widely adopted across industries in India and globally.Q: What maintenance steps are necessary for ensuring pump longevity?

A: Regularly check and lubricate the heavy-duty ball bearings, inspect seals for wear, and ensure the impeller is free from excessive buildup or blockage. Follow manufacturer's guidelines for periodic maintenance and use genuine spare parts for replacements.Q: How does the back pull-out design benefit operational efficiency?

A: The back pull-out structure allows maintenance work on the pump (such as bearing or seal replacement) without disconnecting the suction or discharge piping, significantly reducing downtime and maintenance costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Centrifugal Pump Category

ANSI Series Centrifugal Pump

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Shaft Orientation : Horizontal

Material : Cast Iron, Stainless Steel, Alloy Steel, Duplex Steel

Suction Type : Other, End Suction

Power Source : Other, Electric Motor Driven

Centrifugal Pump for Sugar Industries

Minimum Order Quantity : 10 Units

Shaft Orientation : Vertical

Material : Stainless Steel

Suction Type : Double

Power Source : Electric

DHX Centrifugal Pump

Minimum Order Quantity : 10 Units

Shaft Orientation : Vertical

Material : Stainless Steel

Suction Type : Double

Power Source : Electric

|

Denwell Fluid Controls

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |