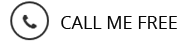

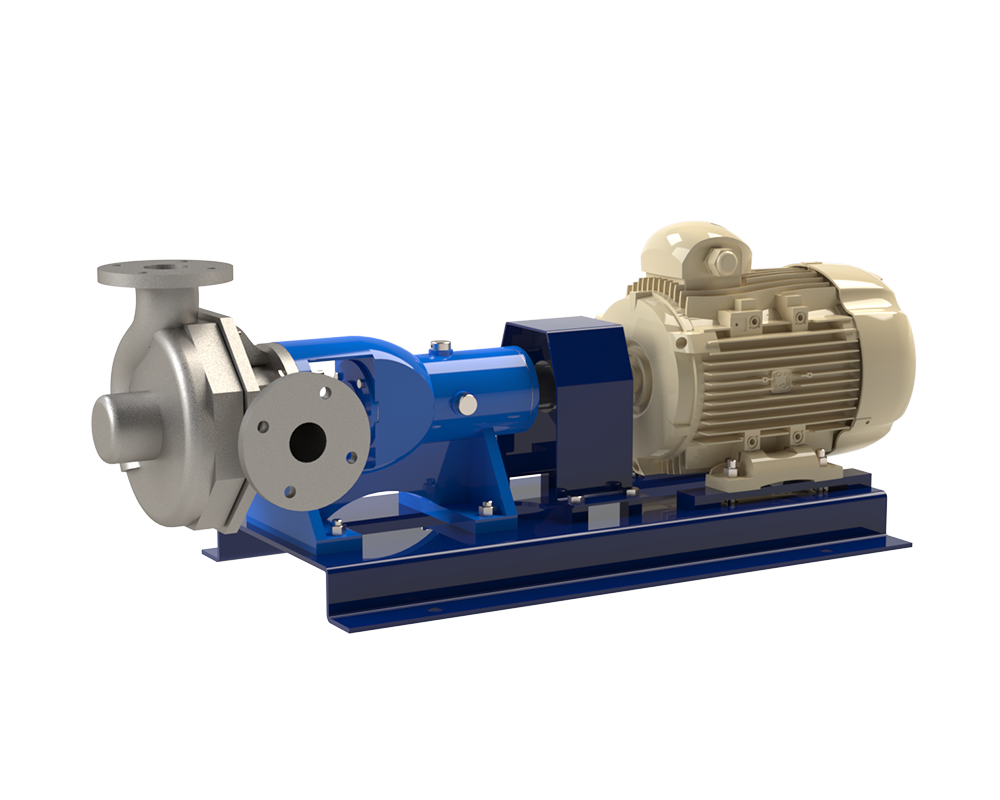

Horizontal Side Suction Pumps

Horizontal Side Suction Pumps Specification

- Theory

- Centrifugal Pump

- Flow Rate

- Up to 600 m/h

- Material

- Cast Iron/Stainless Steel

- Structure

- Single Stage

- Suction Type

- Side Suction

- Volute Type

- Single Volute

- Nozzle Location

- Horizontal

- Shaft Orientation

- Horizontal

- Power Source

- Electric

- Pressure

- Up to 10 Bar

- Temperature

- Up to 90C

- Inlet, Outlet Diameter

- Inlet: 50-200 mm, Outlet: 32-150 mm

- Speed

- 1450-2900 RPM

- Application

- Industrial, Irrigation, Water Supply, HVAC, Fire Fighting

- Motor Phase

- Three Phase

- Bearing

- Heavy Duty Ball Bearing

- Mounting Type

- Base Mounted

- Impeller Type

- Closed/ Semi-open

- Cooling Method

- Air Cooled

- Sealing Type

- Mechanical Seal/Gland Packing

- Drive Type

- Direct Coupled

- Protection Class

- IP55

About Horizontal Side Suction Pumps

Denwell Pumps is one of the best Horizontal Side Suction Pump Manufacturers in Ahmedabad, Gujarat. Our products are acclaimed for their superior quality and comply with industry standards to satisfy clients.Engineered for Versatility and Performance

Our Horizontal Side Suction Pumps come equipped with options for both closed and semi-open impellers, catering to diverse fluid handling needs. With flow rates reaching up to 600 m3/h and a wide inlet and outlet diameter range, these pumps fit numerous industrial settings. Their single-stage, single volute construction ensures efficiency and ease of maintenance, making them a preferred choice across industries.

Durability and Protection You Can Trust

These pumps are built to last, featuring heavy-duty ball bearings and IP55 protection class, ensuring resilience against dust and water. The air-cooled design keeps the motor at optimal temperatures, while the horizontal orientation and robust materials (cast iron or stainless steel) provide strength and resistance, even in harsh operational environments.

FAQ's of Horizontal Side Suction Pumps:

Q: How should the Horizontal Side Suction Pump be installed for optimal performance?

A: The pump should be mounted on a solid base as it is base mounted, and aligned horizontally with proper support. Ensure correct nozzle orientation, and use the recommended inlet (50-200 mm) and outlet (32-150 mm) diameters for connection. It is advisable to have a professional technician handle the installation for best results.Q: What sealing options are available and how do they benefit pump operation?

A: This pump supports both mechanical seal and gland packing options. Mechanical seals offer superior leak prevention and reduced maintenance, while gland packing is more traditional, suitable for less demanding applications. Selection depends on the application's pressure, fluid type, and required maintenance intervals.Q: When is it appropriate to use closed versus semi-open impellers?

A: Closed impellers are ideal for clear liquids or fluids with minimal particulates, offering higher efficiency. Semi-open impellers are better suited for handling liquids with some suspended solids or fibrous content, preventing clogging and ensuring smooth operation.Q: Where can these Horizontal Side Suction Pumps be used effectively?

A: These pumps are suitable for a range of applications including industrial water supply, HVAC systems, irrigation, and fire fighting. Thanks to their robust construction and wide material options, they perform well in both municipal and commercial environments across India.Q: What maintenance process is recommended for optimal longevity?

A: Regularly inspect the bearings, seals, and motor for wear, and ensure the cooling system (air cooled) is free from obstructions. Check alignment and lubrication according to the manufacturer's schedule. Promptly replace worn components, whether using mechanical seals or gland packing.Q: What are the key benefits of the direct coupled drive type?

A: Direct coupled drive ensures efficient power transmission between the motor and the pump shaft, resulting in reduced mechanical losses, lower vibration, and extended service life. This setup also minimizes alignment issues common with belt-driven alternatives.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Pump Category

Thermic Fluid Hot Oil Centrifugal Pump

Minimum Order Quantity : 1 Number

Material : Cast steel / Cast iron / Stainless Steel / Alloy Steel

Suction Type : Other, Single Suction

Shaft Orientation : Horizontal

Power Source : Other, Electric Motor Driven

Gland Packing Pump

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron / Stainless Steel / Bronze

Suction Type : Other, End Suction

Shaft Orientation : Horizontal

Power Source : Other, Electric Motor Driven

Centrifugal Hot Oil Thermic Fluid Pump

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Suction Type : Double

Shaft Orientation : Vertical

Power Source : Electric

Centrifugal Process Pump

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Suction Type : Double

Shaft Orientation : Vertical

Power Source : Electric

|

Denwell Fluid Controls

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |