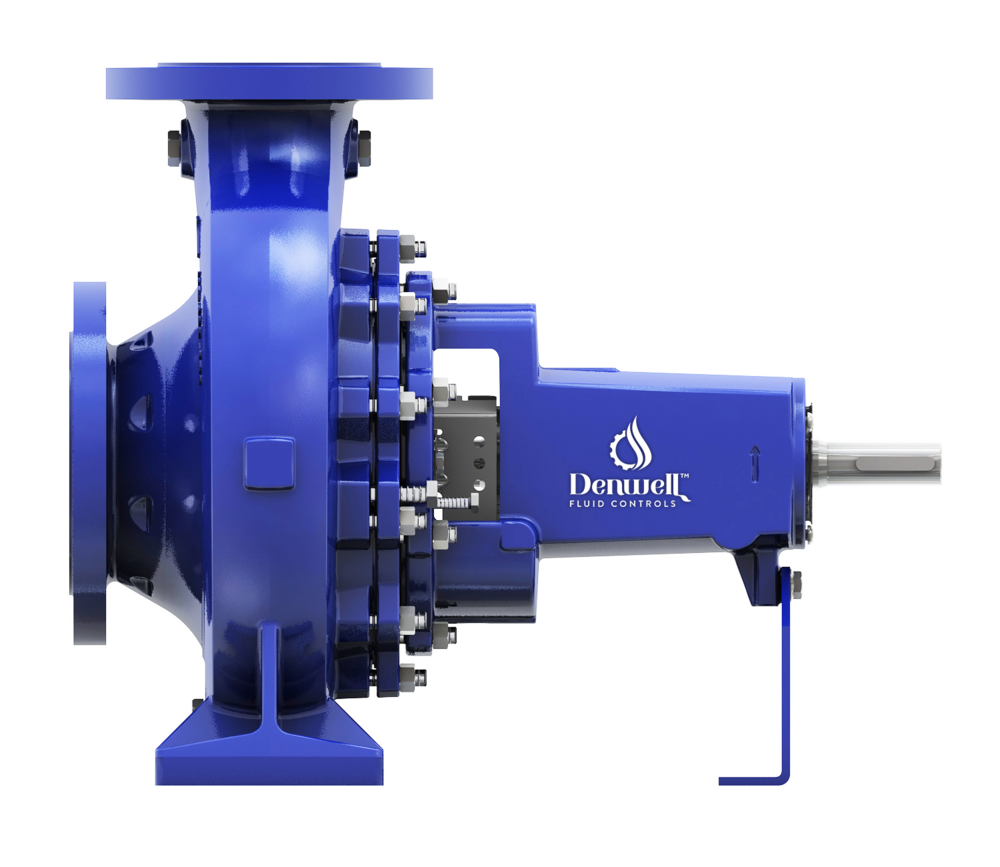

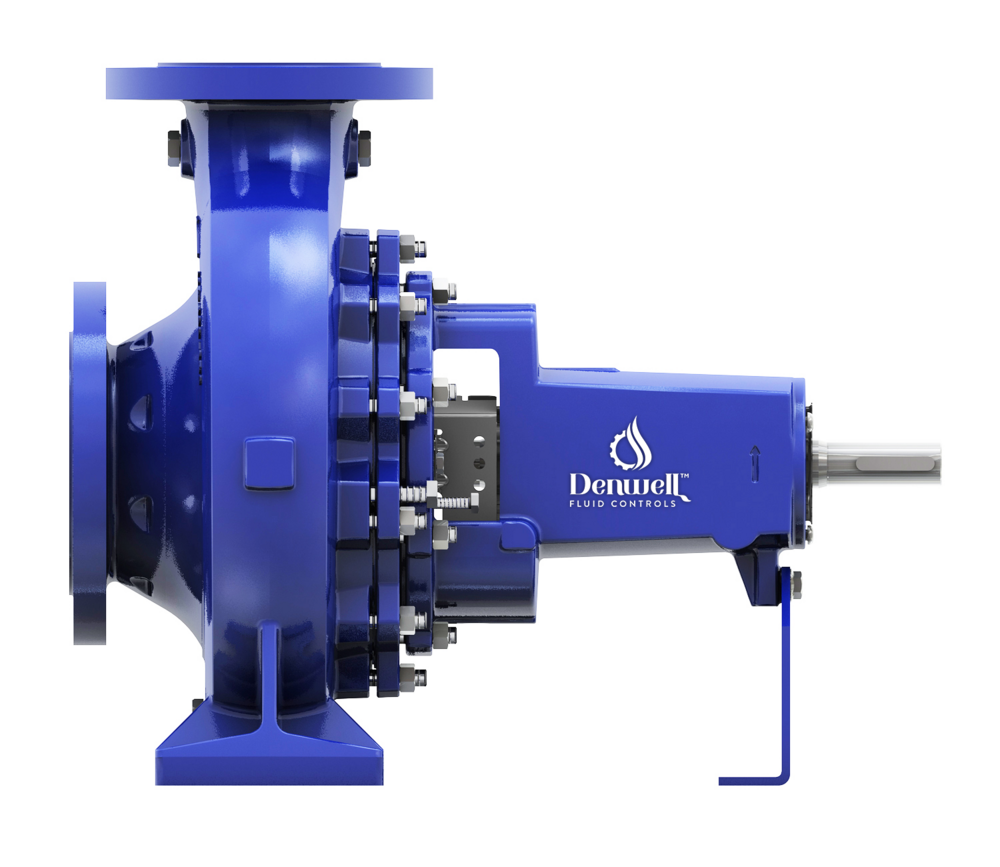

SS 316 Centrifugal Pumps

SS 316 Centrifugal Pumps Specification

- Flow Rate

- Up to 150 m/hr

- Theory

- Centrifugal Pumping

- Material

- Stainless Steel 316

- Structure

- Single-stage

- Suction Type

- Single Suction

- Volute Type

- Single Volute

- Nozzle Location

- End Suction

- Shaft Orientation

- Horizontal

- Power Source

- Electric

- Fuel System

- Direct Drive

- Pressure

- Up to 16 bar

- Temperature

- -10C to +120C

- Inlet, Outlet Diameter

- 25mm x 25mm to 150mm x 150mm

- Speed

- 2900 RPM

- Application

- Chemical transfer, pharma, food processing, water supply

- Max Viscosity

- Up to 200 cP

- Seal Type

- Mechanical Seal

- Mounting Type

- Foot Mounted

- Discharge Head

- Up to 38 meters

- Performance Standard

- IS / ISO 5199

- Motor Phase

- Three Phase

- Protection Class

- IP55

- Surface Finish

- Buffed / Polished

- Pump Size

- Standard and Customized Available

- Connection Standard

- Flange as per ANSI/DIN

- Bearing Type

- Heavy Duty Ball Bearings

- Impeller Type

- Closed Impeller

About SS 316 Centrifugal Pumps

Denwell Pumps is one of the best Centrifugal Pump Manufacturers in Ahmedabad, Gujarat. Our products are acclaimed for their superior quality and comply with industry standards to satisfy clients.Durable Construction for Harsh Environments

Made from premium SS 316, this centrifugal pump is ideal for corrosive and high-demand settings. The buffed and polished surface guarantees longevity and easy cleaning, while the heavy-duty ball bearings and IP55 motor protection enhance operational reliability. Suitable for various sectors, its single volute and horizontal orientation accommodate tough industrial processes.

Versatile Performance Across Industries

The pump efficiently handles liquids with viscosity up to 200 cP, delivering up to 150 m3/hr flow rate. Designed for chemical, pharmaceutical, food processing, and water supply applications, its closed impeller technology ensures consistent output and minimal maintenance. Engineered to meet IS/ISO 5199 performance standards, it fits both standard and bespoke installations.

FAQ's of SS 316 Centrifugal Pumps:

Q: How does the mechanical seal in the SS 316 Centrifugal Pump contribute to its reliability?

A: The mechanical seal helps prevent leakage by forming a tight barrier between the rotating shaft and stationary pump casing. This enhances safety, minimizes maintenance needs, and extends pump service life-especially important for hazardous or corrosive fluids handled in industrial environments.Q: What types of fluids can this pump handle effectively?

A: The SS 316 Centrifugal Pump is ideal for pumping a range of fluids, including chemicals, pharmaceuticals, food-grade substances, and water. Its material and design allow for safe operation with fluids having viscosity up to 200 cP and temperatures between -10C and +120C.Q: When should standard versus customized pump sizes be selected?

A: Standard sizes suit common industrial applications with typical inlet and outlet requirements. Choose customized pump sizes when your process demands unique flow rates, discharge heads, or specific installation dimensions that standard models cannot fulfill.Q: Where can these centrifugal pumps be installed?

A: These pumps are suitable for installation in industrial settings such as chemical plants, pharmaceutical factories, food processing units, and municipal water supply systems. Their robust construction and flange connections (as per ANSI/DIN) support various mounting configurations.Q: What is involved in maintaining an SS 316 Centrifugal Pump?

A: Routine maintenance includes inspecting the mechanical seal for wear, checking the condition of ball bearings, monitoring motor performance, and ensuring the polished surfaces remain clean. Timely lubrication and scheduled part replacement keep the pump running efficiently.Q: How does the closed impeller design benefit pump performance?

A: A closed impeller provides higher efficiency and improved flow rate by minimizing fluid recirculation inside the pump. This is especially useful in applications where consistent pressure and reduced maintenance downtime are desired.Q: What are the advantages of choosing a pump with IP55 protection class?

A: IP55 protection means the pump motor is shielded from dust ingress and water jets, increasing durability and allowing safe operation in challenging industrial environments. This specification supports reliable, long-term use in both indoor and outdoor installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Pump Category

Centrifugal Water Motor Pumps

Price 13000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Material : Cast Iron Body, Bronze Impeller

Shaft Orientation : Horizontal

Suction Type : Other, Single Suction

Gland Packing Pump

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric Motor Driven

Material : Cast Iron / Stainless Steel / Bronze

Shaft Orientation : Horizontal

Suction Type : Other, End Suction

Centrifugal Hot Oil Thermic Fluid Pump

Minimum Order Quantity : 10 Units

Power Source : Electric

Material : Stainless Steel

Shaft Orientation : Vertical

Suction Type : Double

Stainless Steel Centrifugal Pump

Minimum Order Quantity : 10 Units

Power Source : Electric

Material : Stainless Steel

Shaft Orientation : Vertical

Suction Type : Double

|

Denwell Fluid Controls

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |